Frame any space in a flash with Telescopic Panels

Steel Framing Systems (SFS) can have real benefits for interior fit-outs - they are fast to assemble, maneuverable, lightweight, and fire resistant. But SFS are precise, and internal spaces are not; and that presents a challenge. Getting SFS to fit an uneven or non-level space means constant remeasuring, cutting, and snipping. All this adds to installation times, site disruption and waste. That was until Telescopic Panels arrived on the scene.

Steel Framing Systems (SFS) can have real benefits for interior fit-outs – they are fast to assemble, maneuverable, lightweight and fire resistant.

But SFS are precise, and internal spaces are not; and that presents a challenge. Getting SFS to fit an uneven or non-level space means constant remeasuring, cutting, and snipping. All this adds to installation times, site disruption and waste.

That was until Telescopic Panels arrived on the scene.

These adjustable non-load bearing panels are a game-changer – and that is not an exaggeration. They can slide in any direction to fit into an interior space, cutting installation times by up to 50%.

How do Telescopic Panels work?

Manufactured here in New Zealand, the genius of the Telescopic Panel solution lies in its simplicity. The framing has a C Stud, R Telescopic Stud and U Track; with the R Telescopic Stud being smaller than the web and flange. This slight difference in size allows the R Telescopic Stud to slide inside the standard C Stud and provide a precise range of adjustment.

The strong but lightweight panels can be easily assembled; then collapsed, carried upstairs or in elevators, and installed in just minutes.

It is a fast, small footprint approach that dramatically reduces labour costs, site disruptions and noise pollution. These characteristics make them ideal for retrofitting an occupied building, or refurbishing hospitals and schools that cannot close for renovations.

While a recent innovation, Telescopic Panels are already being used in major projects across New Zealand, Australia and North America, including:

- Westfield’s new Two Double Seven shopping complex in Auckland,

- Victoria Lane apartments in Wellington,

- Indigo Hotel and Jubilee Hotel in Queensland,

- A 100-year old building renovation in downtown Boston, Massachusetts.

Ways Telescopic Panels can transform your build

Wall Panels: With two-axis and multi-axis expanding panel configurations (see below), panels can adjust on the spot to the size and angle of any opening, with doors and windows remaining level and plumb.

Soffit Panels: Soffit panels configurations (see below) can quickly adjust to an exact height and a perfect level.

Bulkheads: Forget onsite adjustments for bulkhead spaces. Just line the panels up and drop to fit the area and line. Wiring up downlights is a breeze too with pre-cut service gaps.

Raked or Vaulted Ceilings: Contemporary or period homes with arbitrary designs are easily accommodated. Slide-to-fit telescopic panels can match the space and eliminate onsite reworking and waste.

Refurbishment: Where space and access is limited on multi-storeyed refurbishment projects, lightweight Telescopic Panels can be retracted and carried to location, or flat-packed and assembled in place.

Double T Installation: Framing out between pre-cast concrete double T flooring systems can be done in a fraction of the time it takes using traditional methods. Pre-cut telescopic components effortlessly adjust to fill the space perfectly.

3 configurations to meet all challenges

While Telescopic Panels can cover a multitude of applications, there are only three basic configurations required, further simplifying your workflow:

|

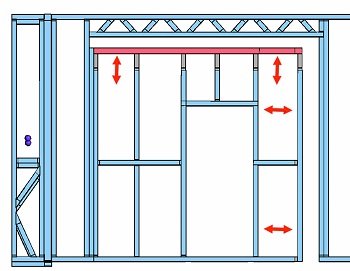

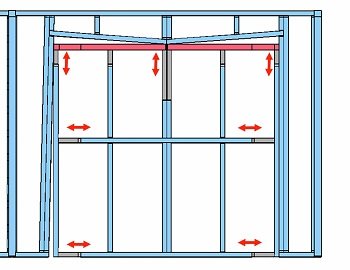

Two-Axis Expanding PanelsTwo-Axis Expanding Panels adjust upwards and outwards to fill the available opening. Within the frame itself, doors and windows remain perfectly square. |

|

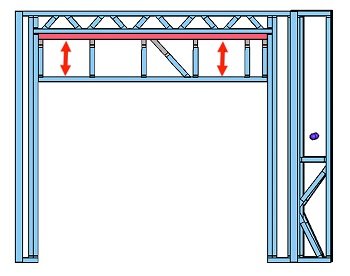

Soffit PanelsSoffit Panels adjust up or down across the frame to a set height. This makes accurate levelling up a breeze, as allowance can easily be made for non-level horizontal settings. |

|

Multi-Axis Expanding PanelsMulti-Axis Expanding Panels adjust upwards and outwards on both sides. This allows for different angles within the available opening. |

How to get sorted with Telescopic Panels for your next job

Wondering how to get started? Depending on the complexity of your project, you can now order our telescopic panel framing in one of the following two ways:

Telescopic Designed Panels

If you are working with full design plans with precise requirements, then we recommend our Telescopic Design Panels solution.

We will take your design files, create shop drawings, and use our software to load these on to our X-TENDATM 3600 machine. The machine will manufacture every component you need with millimetre accuracy, including details such as pre-punched fixing holes and service holes.

Your panels can be produced just-in-time, then flat-packed, or partly pre-assembled and transported to site, ready for your team to install.

With this approach there is no need for remeasuring, snipping and cutting onsite, which means less waste to remove at the end of the job - saving you even more on time, labour and materials.

3m x 3m Kitset Panels

For many projects, our 3m x 3m Kitset Panels are ideal. They are ready to go, easy to install and do not require any design details. This makes them the perfect go-to solution for fast fit-outs of interior spaces.

Panels are delivered flat-packed and can be carried by one team member. After you measure the space, you can snip the frame, assemble the panel and fix it in position. This whole process takes minutes, not hours.

Unlike timber, any waste after snipping frames is easy to remove and is 100% recyclable.

Find out more about Telescopic Panels

If you want to find out more about our Telescopic Panels you can visit the Telescopic Panels product page, download the brochure and installation guide, or contact the team at Rollforming Services.

We can answer all your questions and help you find the right solution for your project.

Get in touch

We encourage you to furnish us with as much detail as possible.

That way we can assist you with the best solutions based on your requirements quickly.