150mm Framing

150mm Framing

Rollforming Services 150mm Framing is run from AXXIS® Steel for Framing using Howick FRAMA™ technology. So you know your framing is strong, straight and built to last.

The RFS 150mm Framing replaces its timber equivalent and can be used in a myriad of applications. The 150mm Framing residential applications include high stud walls, mid-floors and roof panels. The 150mm Framing can also be used in the commercial environment, for internal and external walls, mid-floors, inter-tenancy walls and fire-rated walls.

Steel framing is straight and true, and gives a high-quality finish.

Our 150mm Framing is manufactured with precision, allowing for straight walls, square corners and high-quality finish. You will find it easy to fit internal linings, kitchens and cupboards. Our steel framing stays straight for its entire life; it does not contract or expand through changes in moisture, nor does it warp, twist, sag or shrink, eliminating many of the maintenance issues that create builder call-backs.

Speed of construction and easy to work with

We supply the 150mm Framing pre-assembled or flat packed deliver to site to be assembled. Frames are clearly marked so you will know where it all goes.

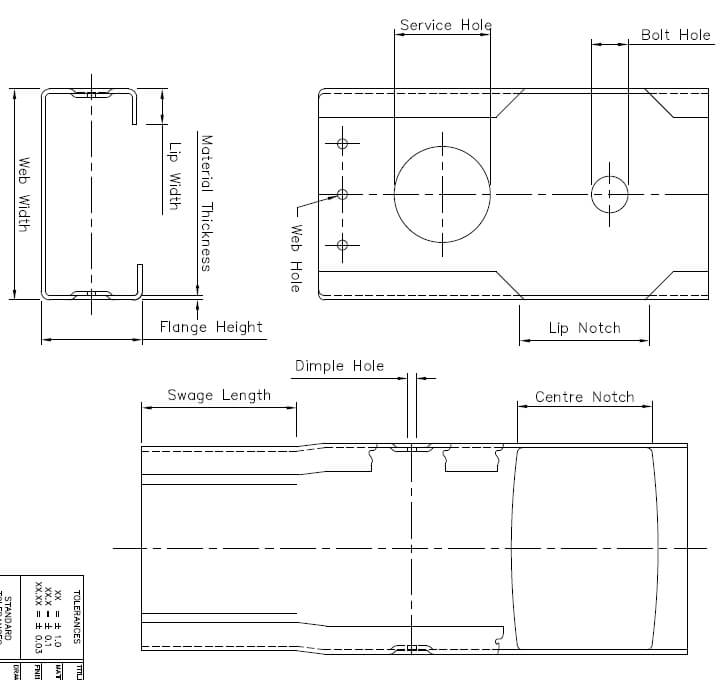

Frame components are easily assembled as they are self-locating. All punching and fixing holes are placed with pinpoint accuracy during manufacture, making it easy for subcontractors to work with. And as steel does not absorb moisture, you do not have to wait for frames to dry, which saves you more time.

Less re-work and wastage

Our 150mm Framing remain sturdy and true for years to come, lowering frame movement issues, and builder call-backs. Precision accuracy in manufacturing the frame components means re-work and wastage are kept to a minimum. It is also lighter, at approximately one-third the weight of timber frame, which makes it easier to move around onsite.

Stronger and durable

Our 150mm Framing is manufactured from Axxis® steel, a New Zealand Steel product, which is designed for New Zealand houses and buildings, and made from galvanised, high tensile steel - built to last.

Our 150mm Framing does not support the spread of fire, and has great seismic and wind load strength. It does not rot, support mould, or suffer from borer or other insects, and is protected against corrosion in a well-constructed building.

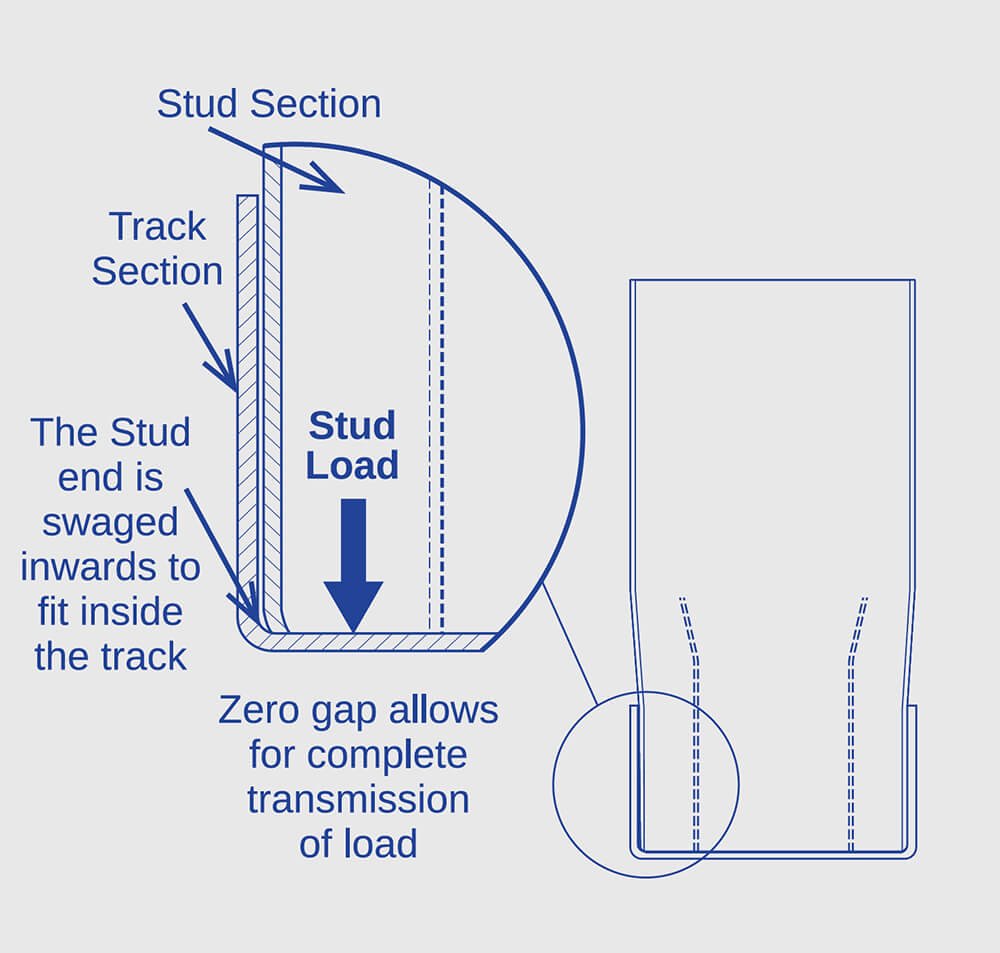

The unique end-bearing stud of our 150mm Framing allows for construction of load-bearing and multi-storeyed structures by allowing the stud, rather than the fixing, to carry the load exerted on the frame.

Healthy and safe

Steel also has none of the additional preservative chemicals associated with timber, which makes a real difference to the health of builders and tradesmen working with the product. It is electrically safe and fire resistant, and a healthy option for homeowners as steel does not support the growth of mould or rot.

- Frames are designed using the compatible framing software such as Vertex, Revit, Sketch Up, Framebuilder MRD, Truss D&E, Tekla and the Howick Panel Software.

- If you have a small project and would like to draw your own design, download the free Howick Panel Software from here.

- We can also provide detailing service for all projects, just get in touch with us to discuss your project.

- Our 150mm Framing is designed to be used with all other elements of framing, joist and truss profiles. We are happy to co-ordinate with other suppliers and sub-contractors to deliver on your project.

- The design software for framing generates machine files which are fed into our roll-forming machines, which in turn manufacture the steel profiles, pre-punched and cut to length.

- The profiles are either pre-assembled in our factory, or flat packed to be delivered to site to be assembled.

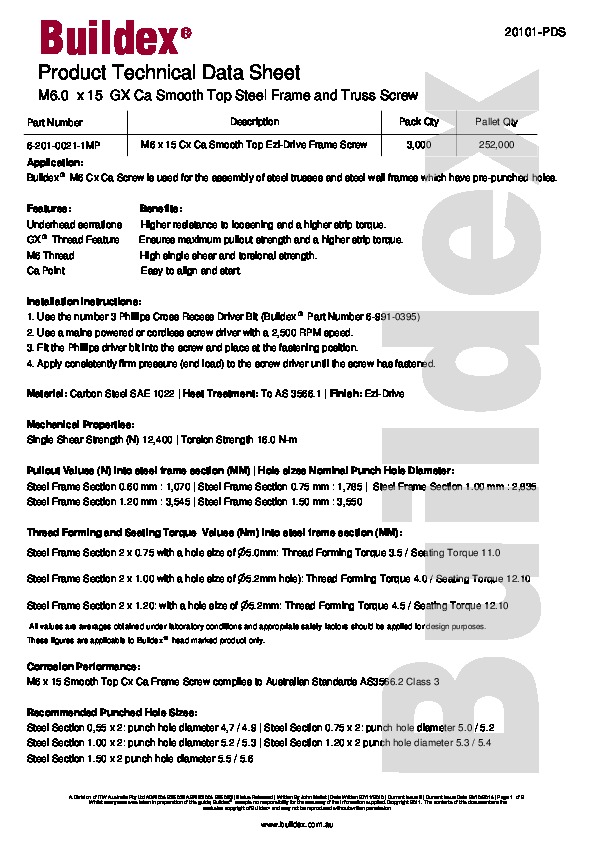

- We provide the fasteners required to screw the pieces together and an easy- to-follow plan.

- We recommend maximum wall dimensions of 3m x 6m for pre-assembled walls

- For flat pack bundles, available transport and handling equipment determines the longest length.

Steel framing requires very few specialist tools. No welding equipment is required. Here are some items you will need:

- A good quality set of aviation snips (left cut – red handle, right cut – green handle, straight cut – yellow handle)

- A cordless impact driver with a selection of bits including 150mm bits for screwing into deep corners

- A 34mm hole saw to make any additional service holes, or a 34mm stud punch to cleanly create service holes without sharp edges or swarf.

The National Association of Steel Framed Housing (NASH) has published documents with NZ Building Code compliant design solutions for cold-formed steel framing used in low-rise buildings including houses and low-rise commercial buildings. Download here

The documents include:

- NASH Standard for Residential and Low-rise Steel Framing Part 1: Design Criteria

- NASH Standard Part 2: 2019 Light Steel Framed Buildings

- NASH Building Envelope Solutions

- Building Basics - Lightweight Steel Framing 2nd Edition

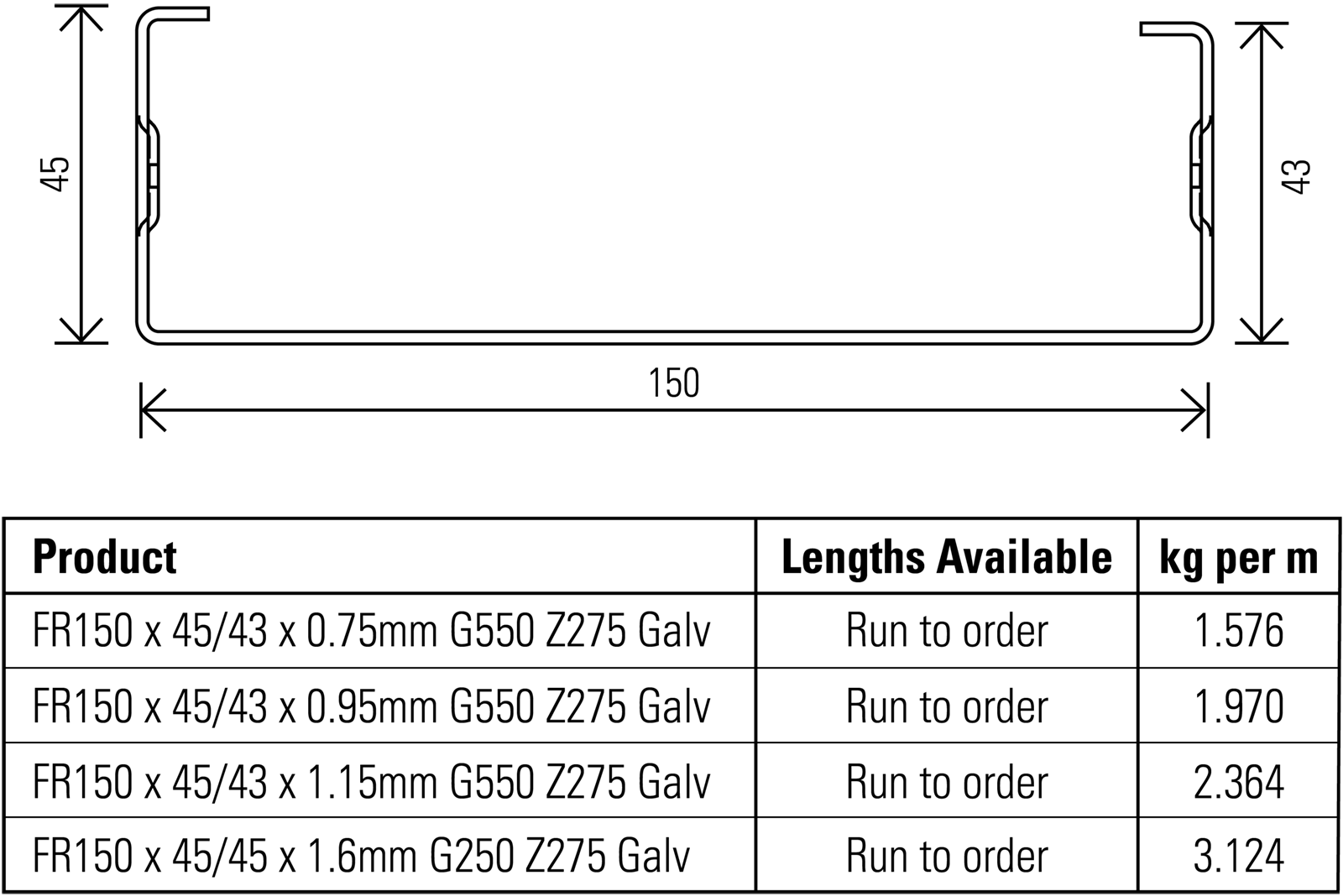

Our 150mm Framing is manufactured from AXXIS® steel and backed by New Zealand Steel’s 50-year Durability Statement. It is hot-dipped galvanised steel with coating weight of Z275.

To ensure durability, run-off from, or contact with, materials which are incompatible with zinc should be avoided.

The 150mm Framing must be kept dry during storage as water present between close stacked sections will cause premature corrosion. Once the frames have been stood up onsite and the building is wrapped, give the upper frames a quick blow-down to remove loose swarf and excess moisture, and vacuum out of the bottom track before organising a pre-line inspection.

Cutting is preferably done by tin snips, hacksaw or cold cut saw. When using abrasive disc blades, care must be taken to ensure the flammable swarf produced does not affect other materials, and the burred edge should be cleaned off at the completion of cutting.

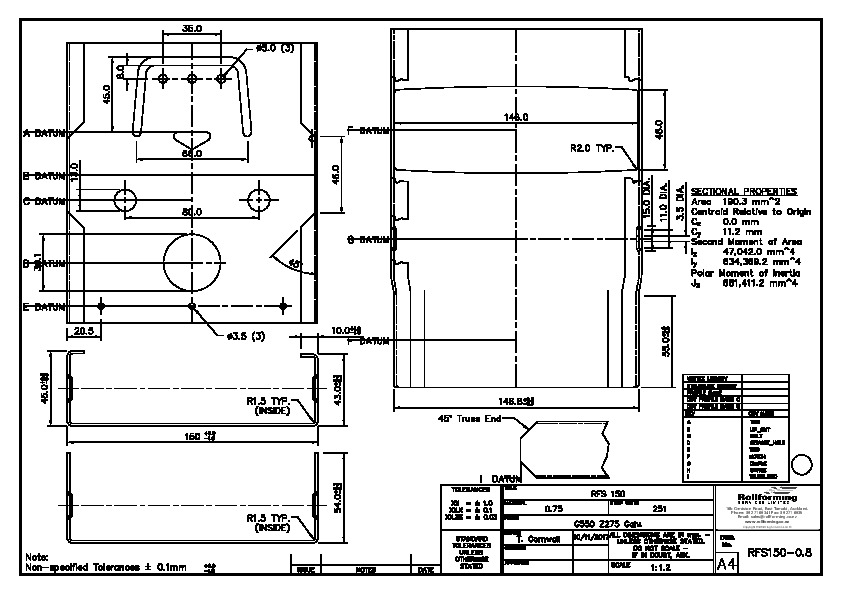

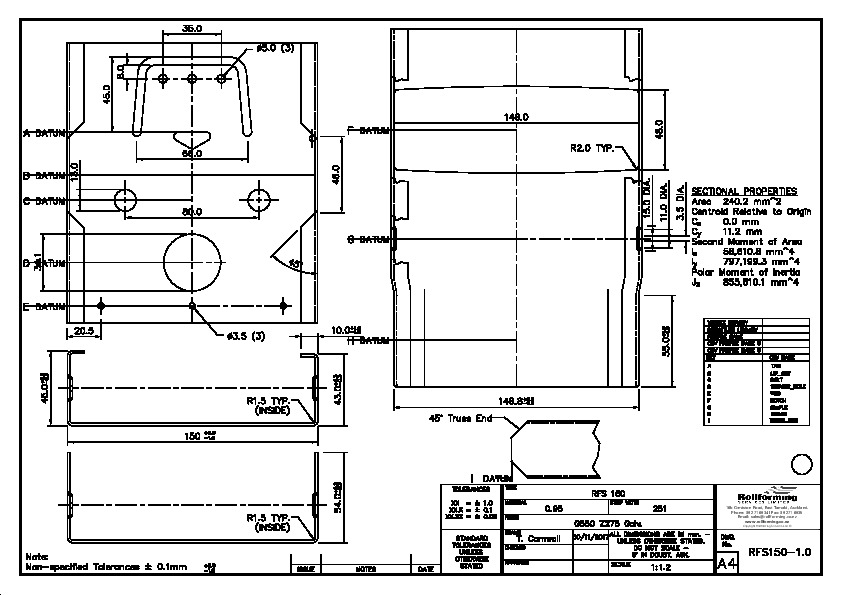

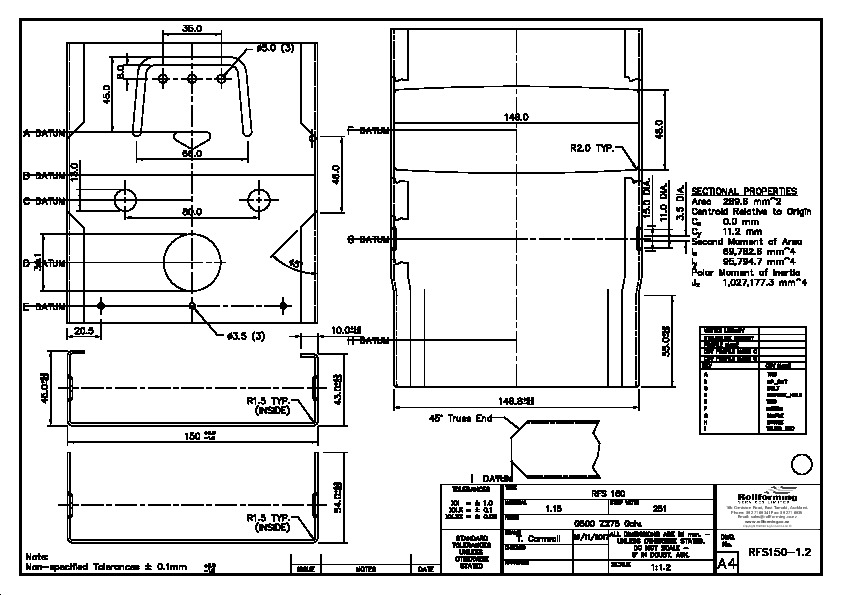

Notes:

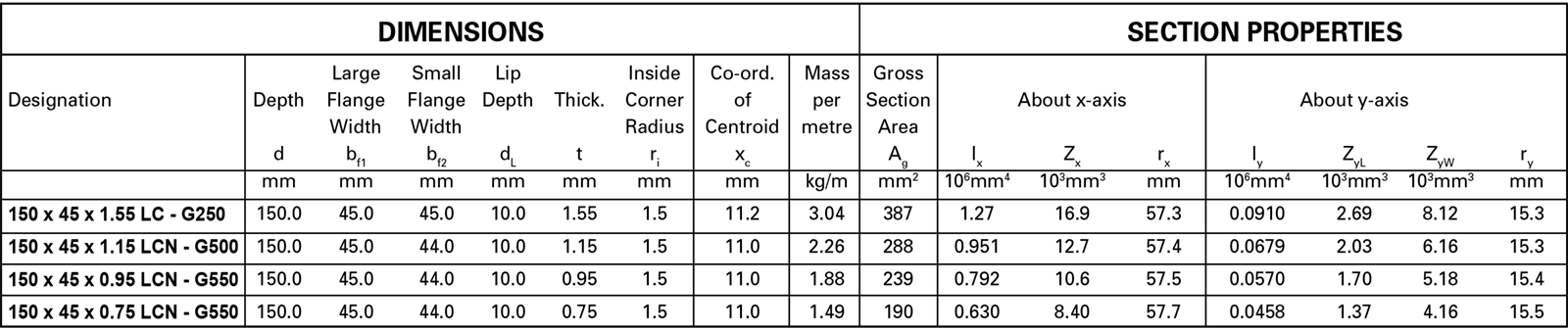

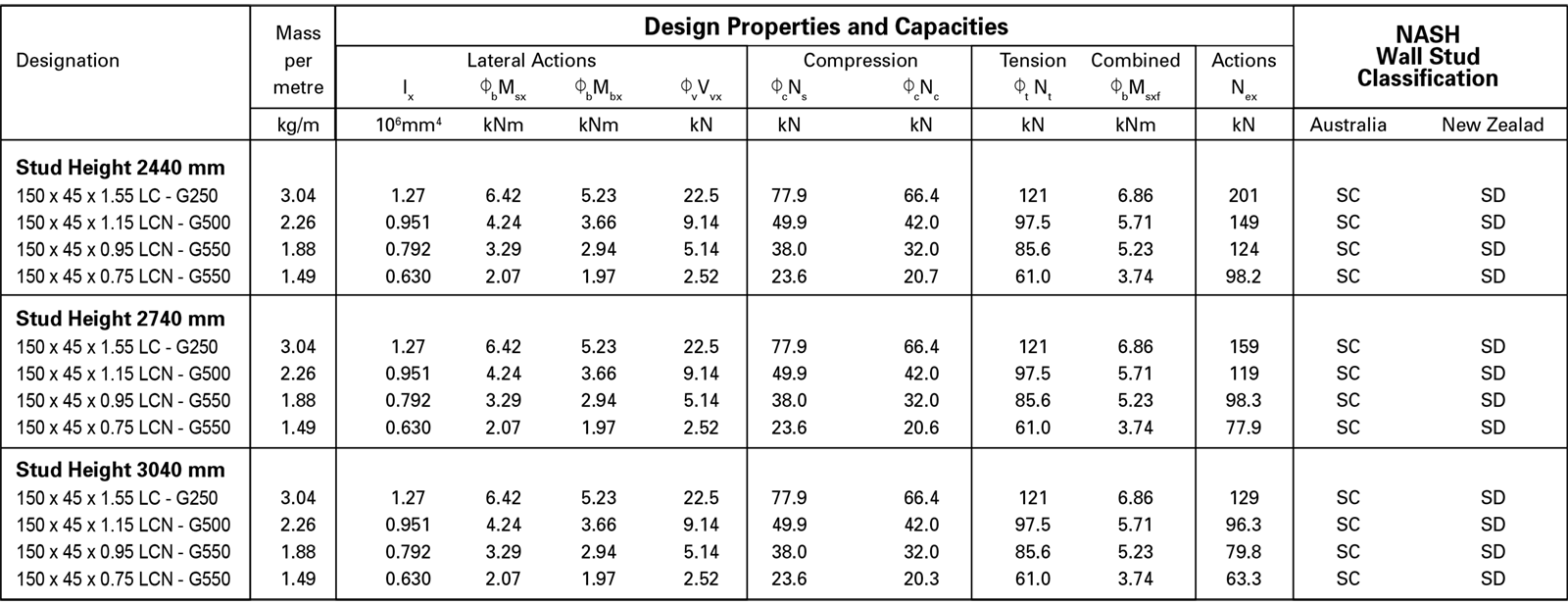

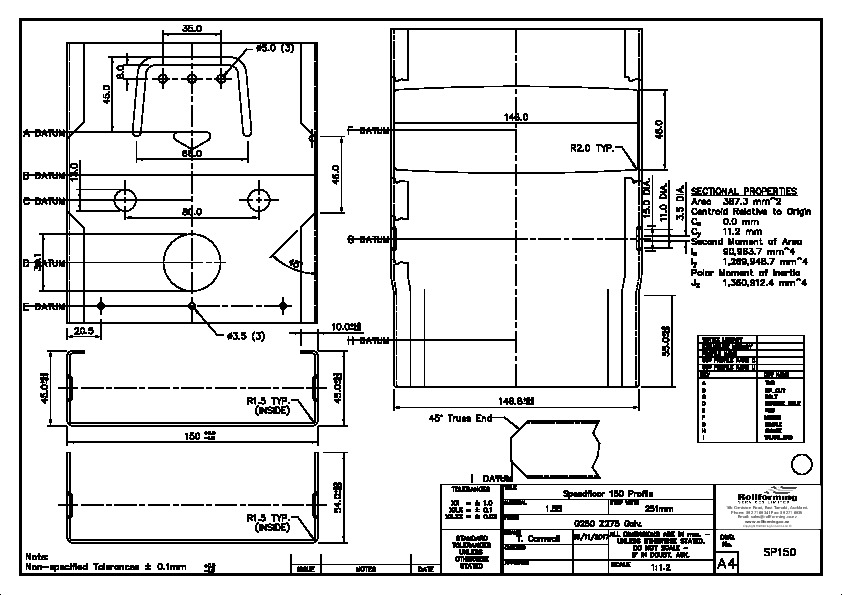

- Calculations of section properties are in accordance with AS/NZS 4600.

- Thickness refers to the base metal thickness (BMT).

- Properties are calculated for an equal flange lipped channel using the average flange width.

References:

AS/NZS 4600 Cold-Formed Steel Structures.

- NASH Standard (NZ), Residential and Low-Rise Steel Framing, Part 1: Design Criteria.

- NASH Standard (Aust.), Residential and Low-Rise Steel Framing, Part 2: Design Solutions.

- NASH Standard (Aust.), Residential and Low-Rise Steel Framing, Part 2: Design Solutions.

- NASH Handbook (Aust.), Best Practice for Design and Construction of Residential and Low-Rise Steel Framing, Chapter 3.

- For full design Tables please request a copy of our Full Design Capacity Tables Document.

Get in touch

We encourage you to furnish us with as much detail as possible.

That way we can assist you with the best solutions based on your requirements quickly.