Tophat Purlins

Tophat Purlins

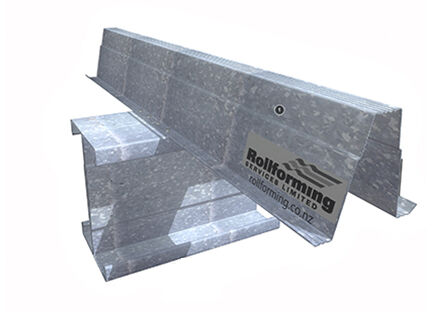

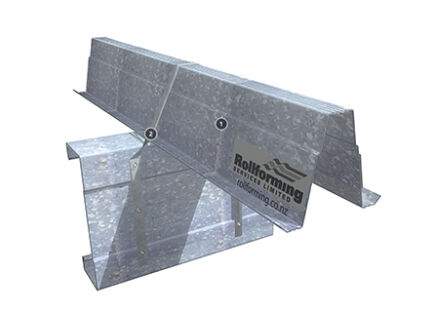

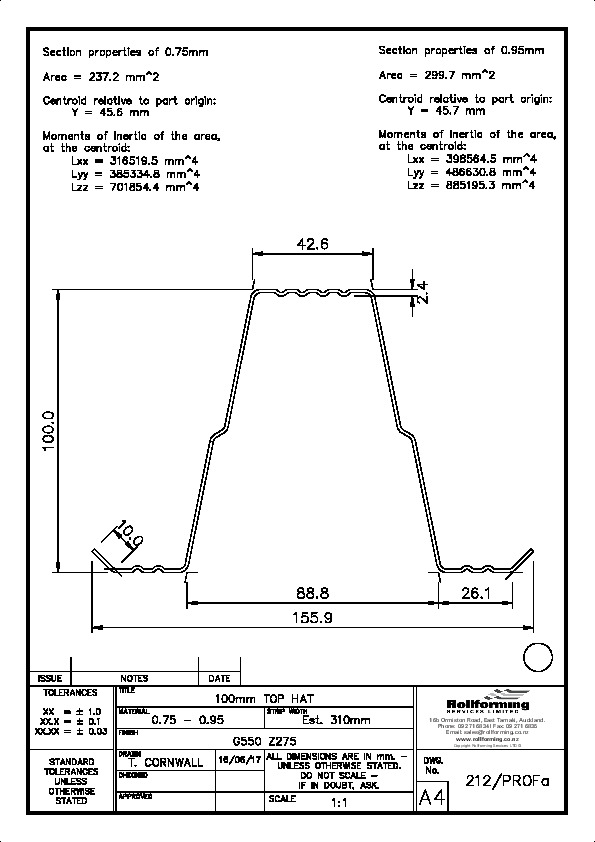

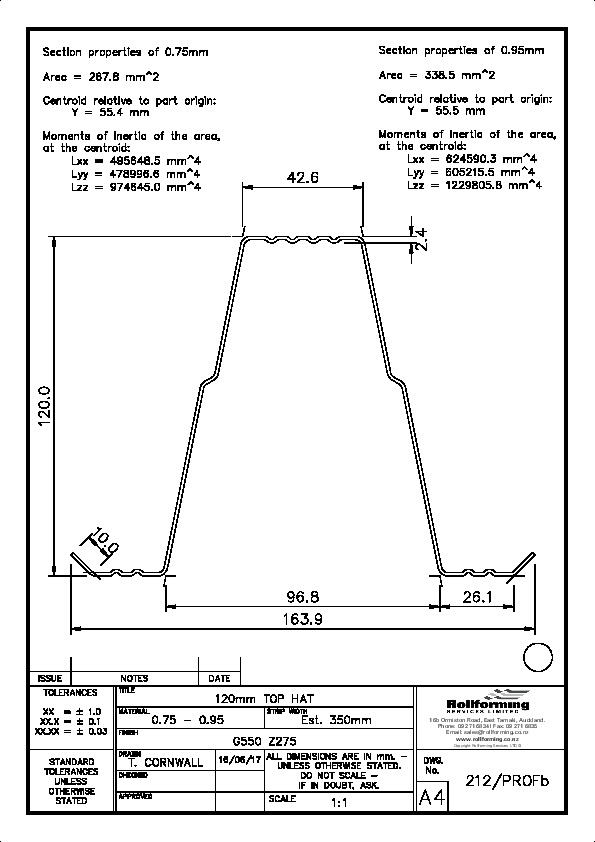

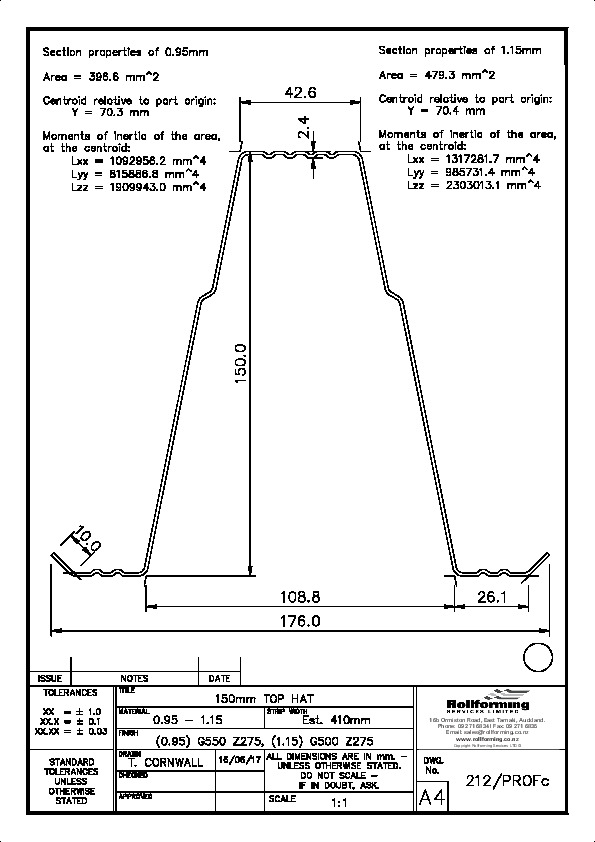

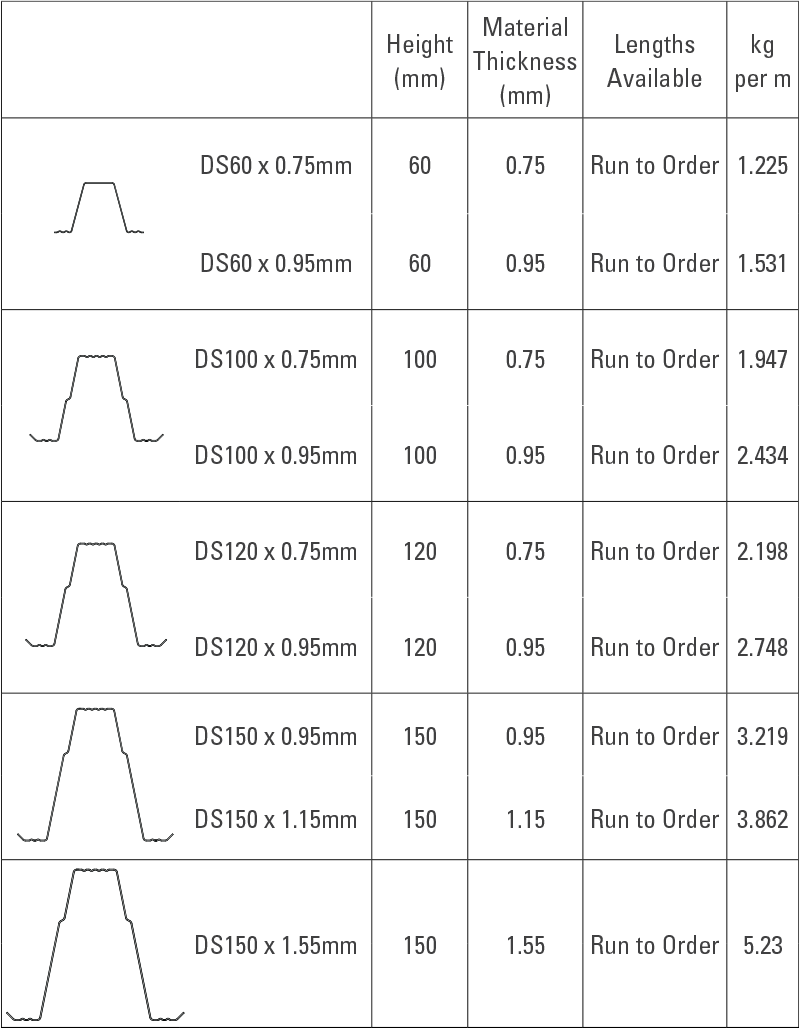

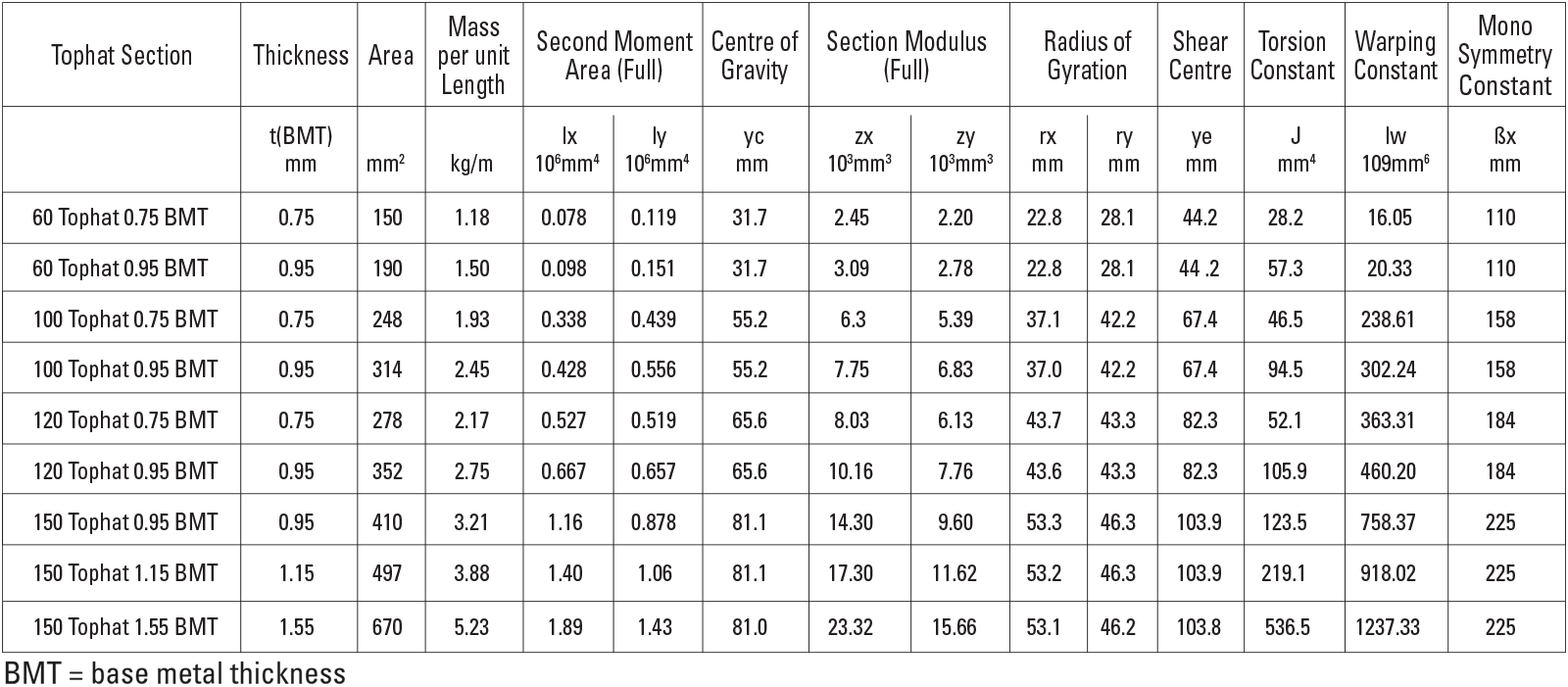

Rollforming Services' Tophat Purlins are a versatile, lightweight, economical and an easy-to-use product for roof purlins, wall girts, floor joists, and many other applications such as carports, fencing and racking.

Tophat Purlins are a versatile and an easy to use product, typically used as roof purlins and wall girts, in applications such as carports, fencing, racking, farm buildings, and light commercial sheds.

Ideal for spans from 3 to 7 metres, Tophat Purlins provide a lightweight and economical alternative to standard timber beams or steel C-purlins.

- Tophat Purlins are fastened directly to their supports with Tek screws, which results in a saving on cleats.

- Tophat Purlins do not twist because of their symmetrical section, so no braces or nogs are needed.

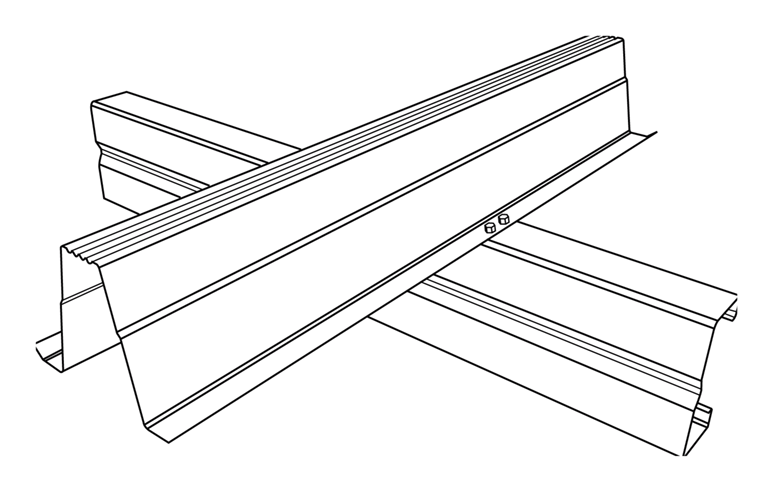

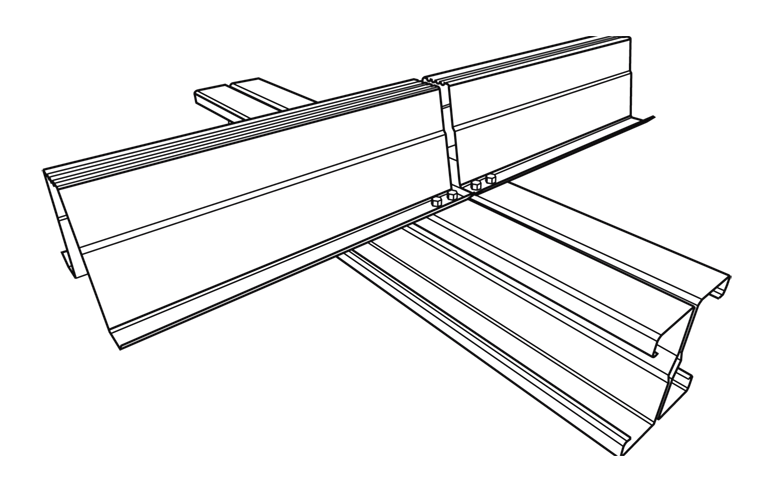

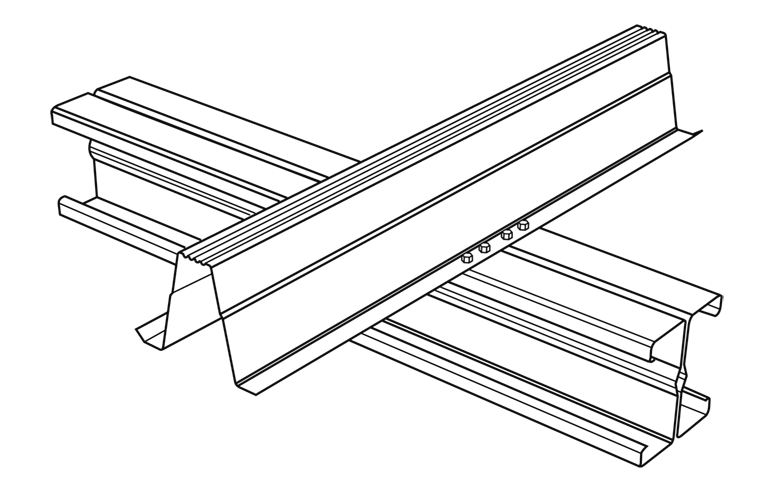

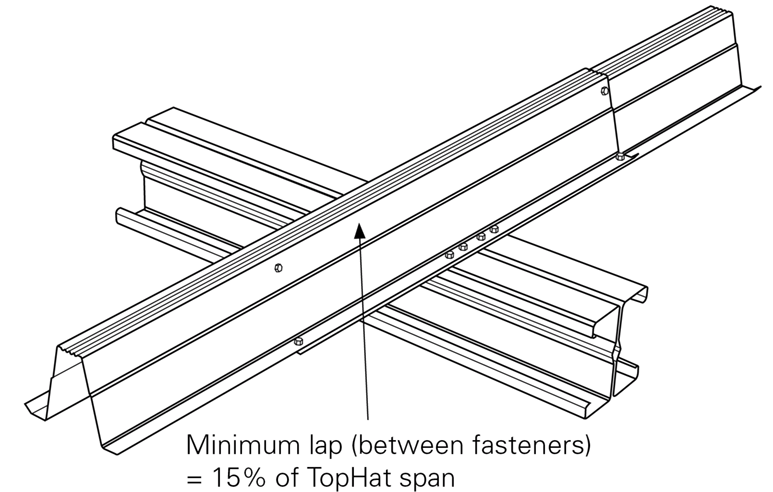

- The Tophat profile is easily lapped for optimal performance.

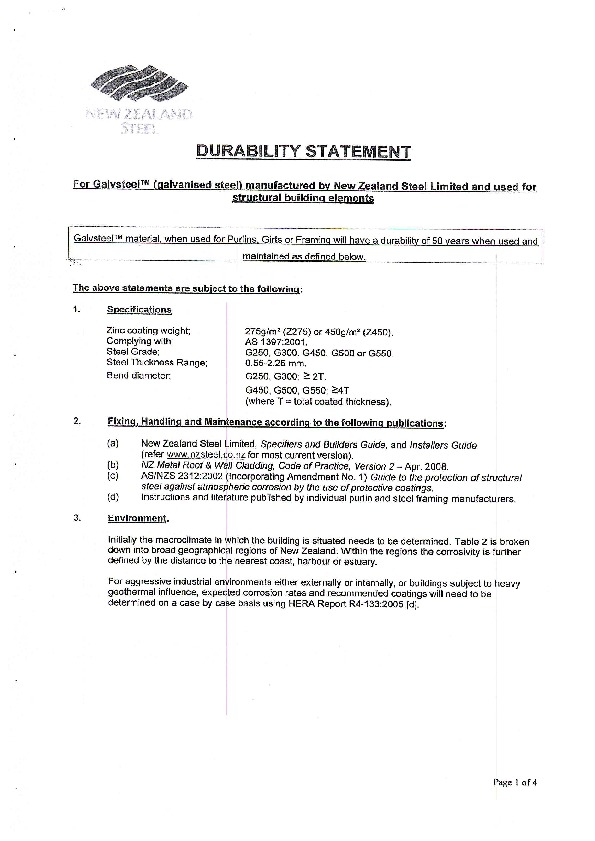

Tophat Purlins are rolled from G550 steel hot-dipped galvanised with coating weight of Z275

Tophat Purlins are manufactured from G550 steel hot-dipped galvanised with a coating weight of Z275. This gives good protection in most exposed internal environments, and for external use in moderate coastal environments. Z450 galvanised steel coating is also available upon request.

To ensure durability of product, please note the following:

- Where used in a lined interior dwelling, a thermal break should be installed between the Tophat and the cladding to avoid thermal bridging.

- Where sections are exposed to salt spray but not rain, maintenance is required to remove any build-up of salt deposits on the surface.

- Run off from, or contact with, materials which are incompatible with zinc should be avoided.

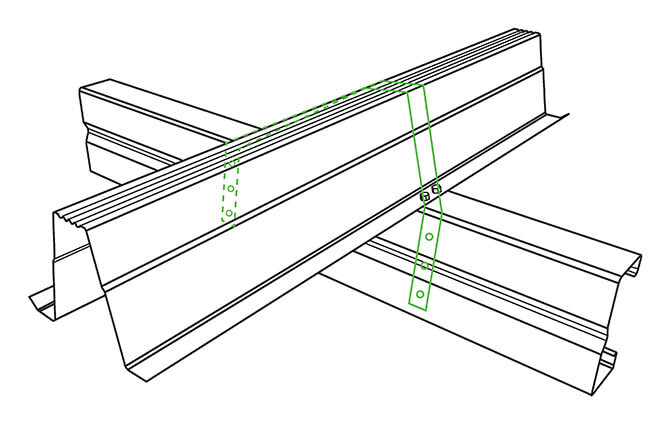

Use 14 gauge Tek screws.

- Typically

- use 2 screws at simple ends

- use 4 screws at lapped supports

With the exception of the following:

- For fittings to cold rolled purlins with thickness less than 2.5mm BMT

- use 2 screws at simple ends

- use 4 screws for the 150mm Tophats at simple ends

- For lapped supports use

- 4 screws for the 60mm Tophats

- 6 screws for the 100mm Tophats

- 8 screws for the 120mm & 150mm Tophats

- OR use strap detail as required

Tophat Purlins must be kept dry during storage as water present between close stacked sections will cause premature corrosion. If they become wet, they should be separated and stacked openly to allow for ventilation to dry the surface.

Cutting is preferably done by shear or hacksaw. When using abrasive disc blades, care must be taken to ensure the flammable swarf produced does not affect other materials, and the burred edge should be cleaned off at the completion of cutting. Finish the cut end with a galv spray to add protection.

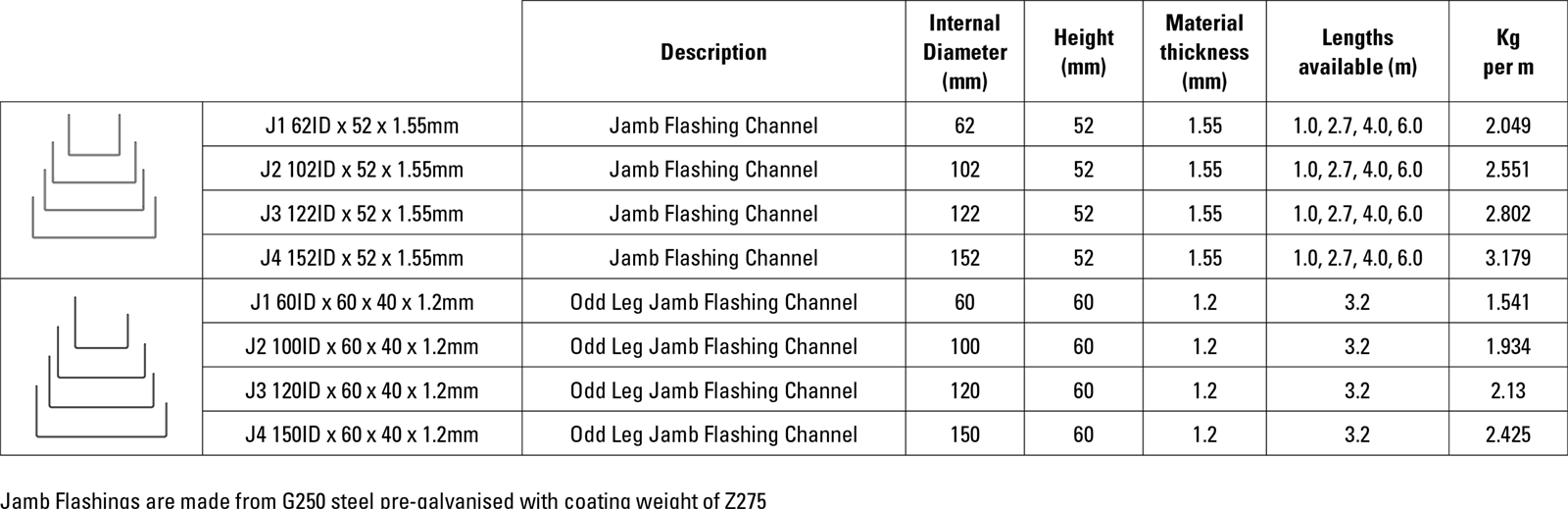

Jamb Flashings

- Jamb Flashings are used where a door or window is cut into the side of a building to flash off the cladding and Tophat girt.

- They are available in two variations, and are made from G250 Z275 galvanised steel

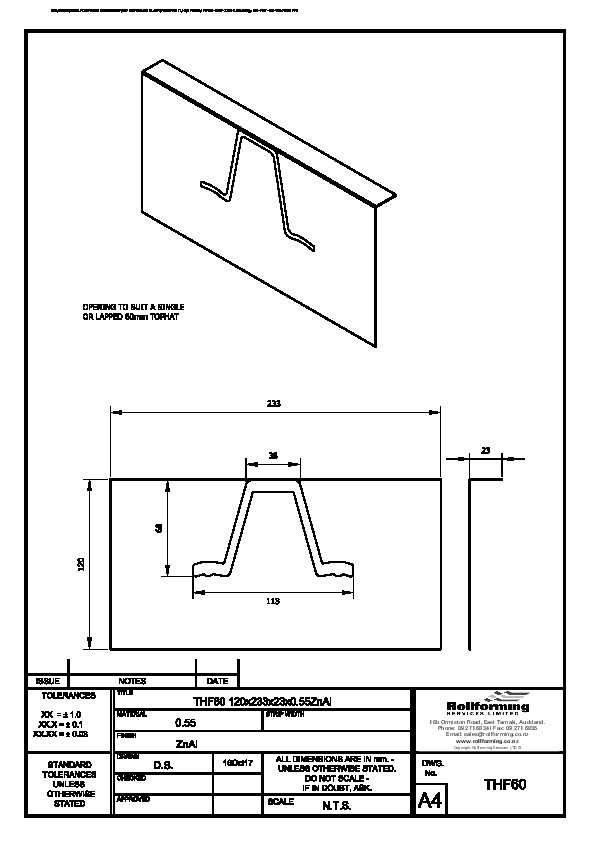

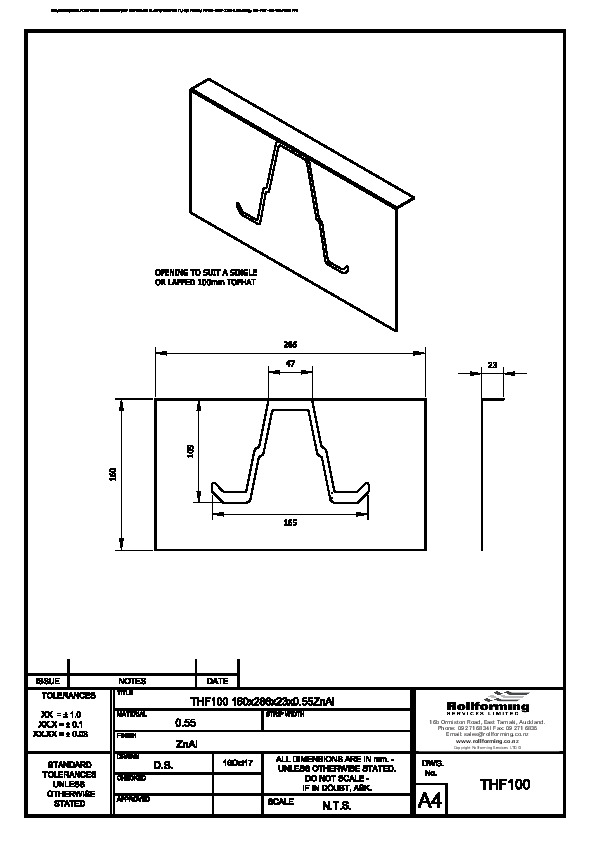

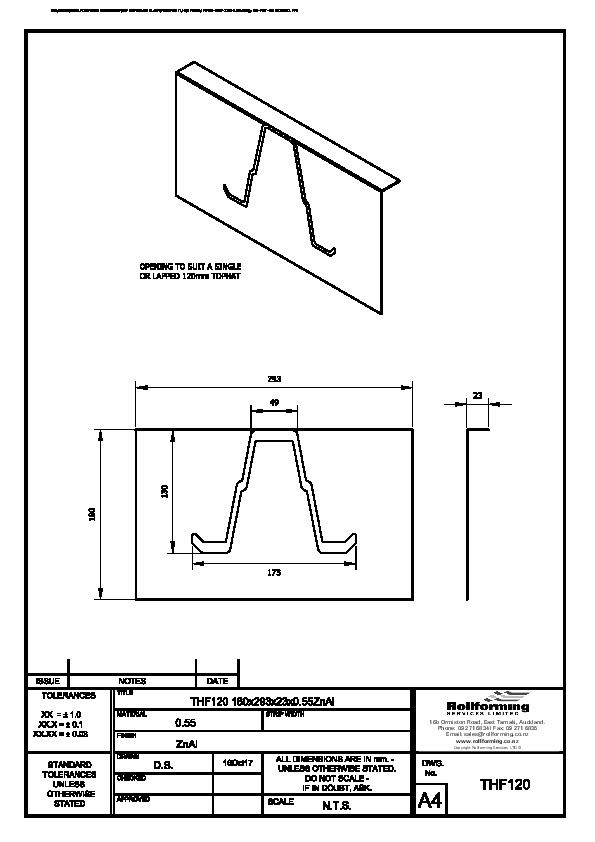

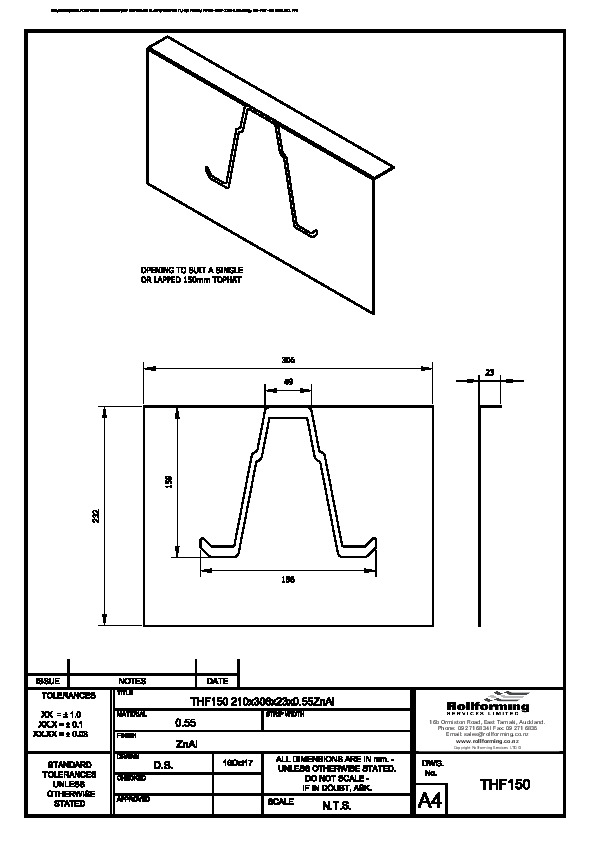

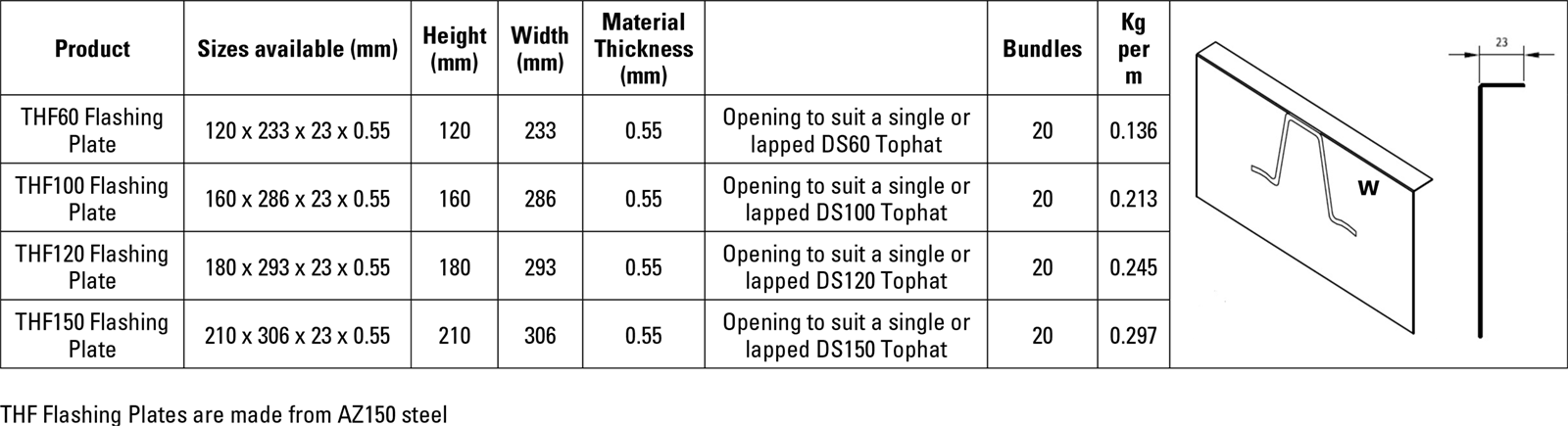

THF Flashing Plates

THF Flashing Plates are used where Tophat Purlins pass through internal or external wall linings and fire-rated wall linings. They provide a neat and tidy hole for fixing of the sheets, which would otherwise be hard to achieve. Lapped Tophat Purlins can also pass through the THF Flashing Plates. Made with AZ150 Steel, they can be spray painted to match cladding if required.

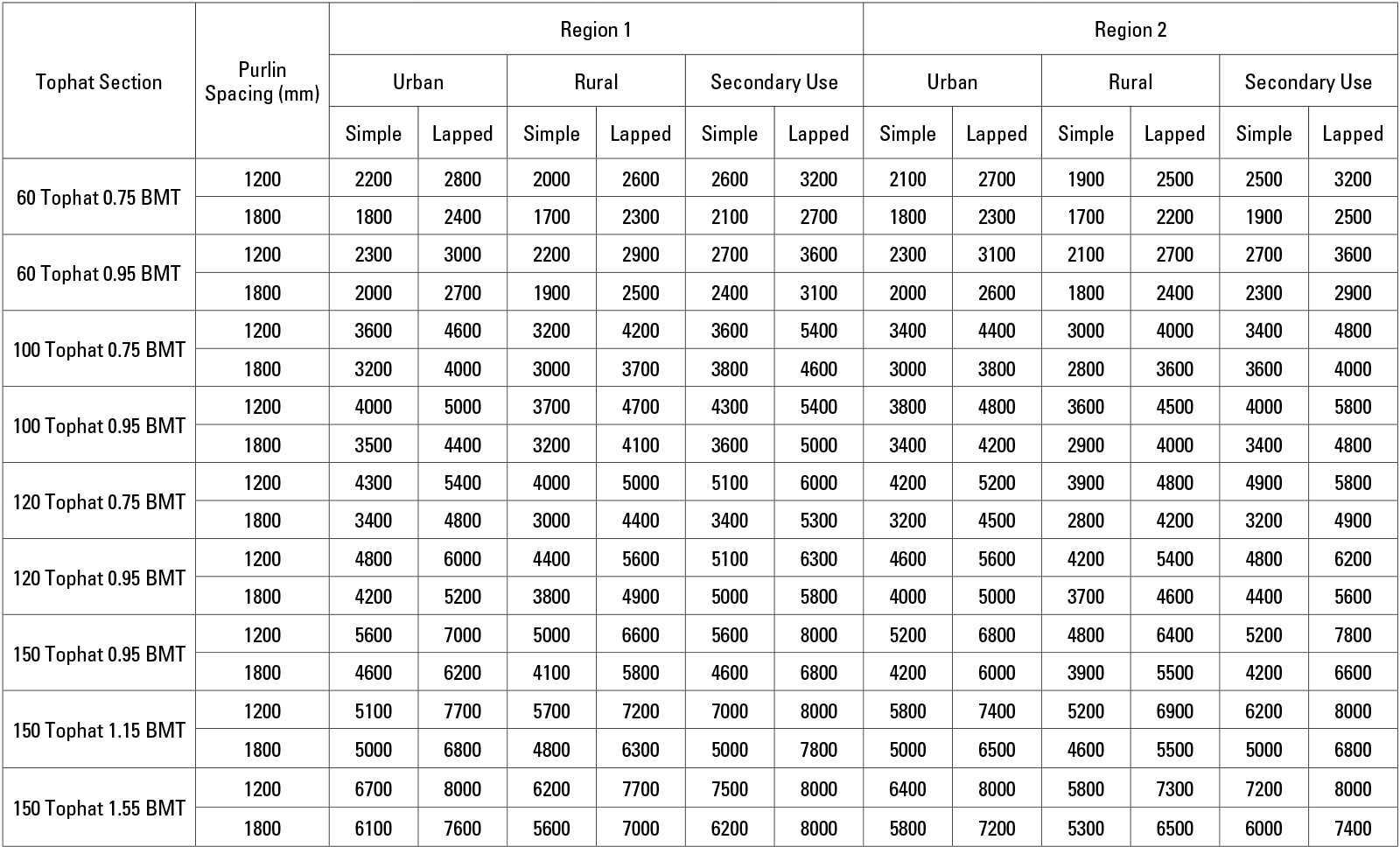

- Region 1 Auckland, Central North Island, South Island (except Marlborough & Southland).

- Region 2 Northland, Wellington, Marlborough, Southland.

- Urban Any Built up area with numerous houses/buildings 3 to 5 metres high (Terrain Category 3).

- Rural Areas with scattered obstructions, hedges, trees, buildings etc. (Terrain Category 2 1/2).

- Secondary Use Buildings of low importance (secondary nature) where higher roof deflections are acceptable. In areas with scattered obstructions, hedges, trees, buildings etc. (Terrain Category 2 1/2).

- Snow These tables do not apply for elevations in excess of 300 metres or for Canterbury/Otago/Southland above 50 metres. In these areas “Snow Loads” should be considered by a qualified engineer.

Get in touch

We encourage you to furnish us with as much detail as possible.

That way we can assist you with the best solutions based on your requirements quickly.